On time, every time

Meet your customers’ demands by routing and distributing your stock from within the warehouses to multiple locations – in an intelligent and cost effective manner.

Pronto Xi Supply Chain module gives you full visibility across your entire supply chain – from planning your distribution and forecasting your stock requirements to complete warehouse management. You can move and manage your stock entirely within Pronto Xi by reducing paper-based and manual processes. Through fully integrated products of this module, costs can be minimised through lower inventory and shipping costs as well as data errors and administration overheads.

The Pronto Xi platform can be easily aligned to your supply chain processes via turnkey customisations – so that demand can be matched efficiently to your supply.

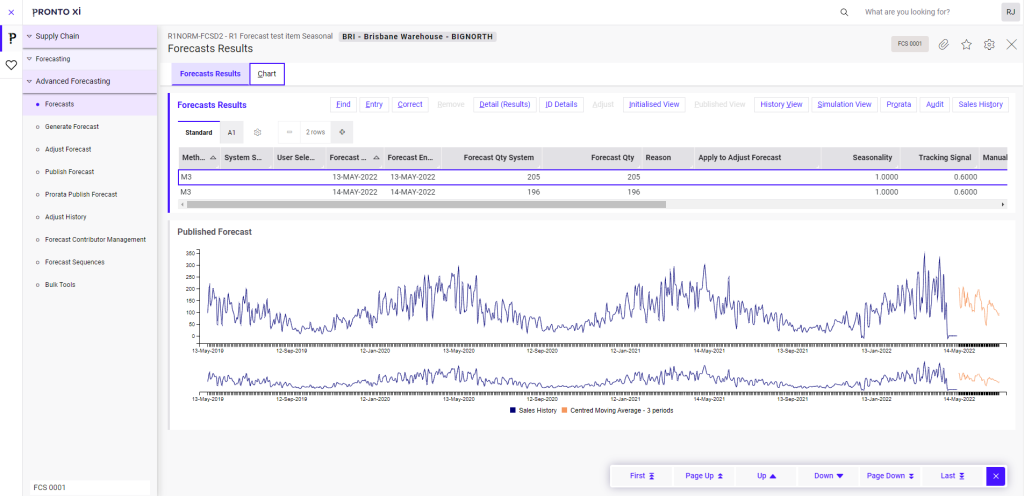

To eliminate unnecessary waste, you can plan and prepare for the future by predicting the trends and customer demands with Pronto Xi Advanced Forecasting. With advanced statistical methods, smoothing and visualisations, cash flows can be improved with lean inventory processes.

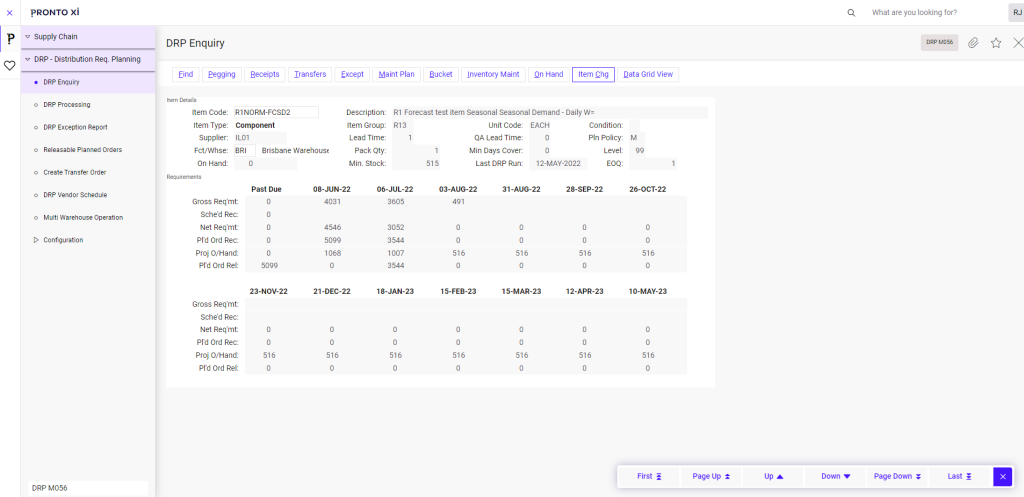

When you have multiple warehouse and factories, Pronto Xi Distribution Requirements Planning (DRP) is a powerful tool to handle complex networks. It helps by optimising replenishment and implementing a time-phased distribution plan so that you can streamline the flow of stock and information between multiple sites. Pronto Xi Warehouse Management System (WMS) is an intelligent, automated system that gives great flexibility and tighter stock control to large or busy warehouses. You can manage a wide variety of functions such as custom warehouse layouts, top-up, replenishment and putaway routines, wave picking, storage zones, smart despatch and more.

Pronto Xi Radio Frequency (RF) and Pronto Xi Scanpack enables a smooth flow of information and inventory throughout your distribution network. RF can transmit orders electronically from Pronto Xi Sales to operators’ portable devices. By replacing paper-based processes, you can increase productivity and reduce human errors for operations like picking, replenishments and putaway. At the same time, Pronto Xi Scanpack increases the accuracy of order fulfilment and warehouse inventory by directly scanning carton and pallet information with barcodes.

Delivery personnel can use the Pronto Xi Proof of Delivery mobile app to obtain signatures or capture images to record a proof of delivery. Manifest and package details are readily available along delivery progress status updates.

To further add efficiency to your supply chain, Pronto Xi Electronic Data Interchange (EDI) can be used to exchange structured business documents with your trading partners via Value Added Networks (VAN). Documents such as purchase orders (PO), purchase order acknowledgements (POA), advanced shipping notices (ASN) and invoices are supported for digital interchange.

Store and maintain unlimited number of supplier products and their details, including technical documentation in Pronto Xi Catalogue. Create inventory records straight from the Catalogue when you receive the products.